Tapir processing techniques

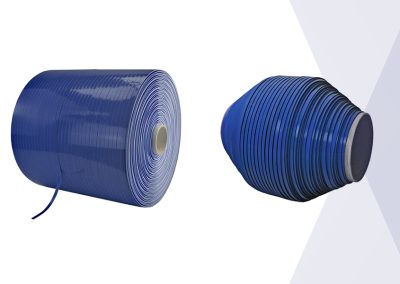

Cross-spooling

Time is money in production environments. Cross-rinsing is generally used in processes that are difficult or impossible to stop. Consider an extrusion process or a printing company where you do not want to stop the machine every 50 meters to allow a roll change to take place. A longer roll length therefore ensures efficient production.

With cross coils, as much length as possible is wound onto a coil, allowing for longer spinning. In this case, think of the spool of thread on a sewing machine: The way you wind it allows you to lose a considerable length.

Anyone who orders online knows the shipping bags for parcel delivery. These shipping bags are made inline. A bag is blown from granulate and the closing strip is immediately applied. The tape for this is on large spools of easily 8 kilometers per roll. The same applies to packaging of, for example, meat products or slices of cheese. There’s a good chance there’s a Tapir tape in your refrigerator!

Specifications cross-spooling

- Core format 3” or 6”.

- Maximum coil width 400 mm.

- Maximum length depends on type of material and width of the tape.

Questions?

Would you like more information about cross-spooling tape?

Contact our experts:

+ 31 591 390 059 / info@tapir.nl